CAD, 3D Printing, & Finishing Techniques

Helix “Orca” Mock Up

The “Orca” was a step towards making TwoPoreGuys’ universal biosensor a reality. The concept of how the device would look and function began as 3D models that were later used for video illustration.

As funding was acquired and investors took an interest, there grew a need for making the 3D illustrations a reality through mock-ups and prototypes.

A few rough prototypes began as box-shaped sensors, soon moving to become hand-crafted models before 3D printing was looked at as a solution.

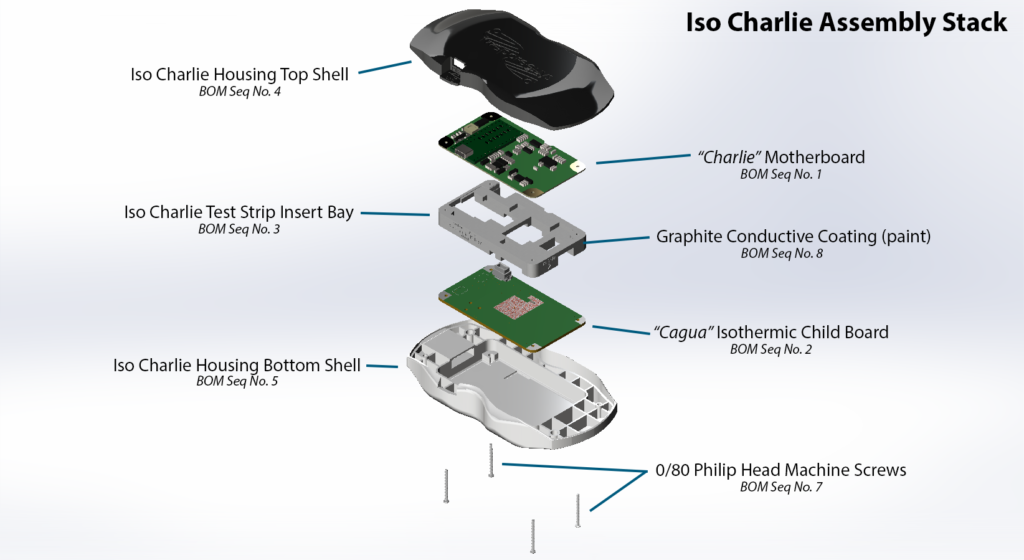

I took on redesigning 3D models in CAD in SolidWorks to make them usable for printing. Through outsourced 3D printing vendors such as Shapeways and Fictiv, I was able to produce and refine designs for the first Orca mock-ups.

The quality of prints coupled with the speed and flexibility to produce parts in-house led to more refined and finished Orca cases.

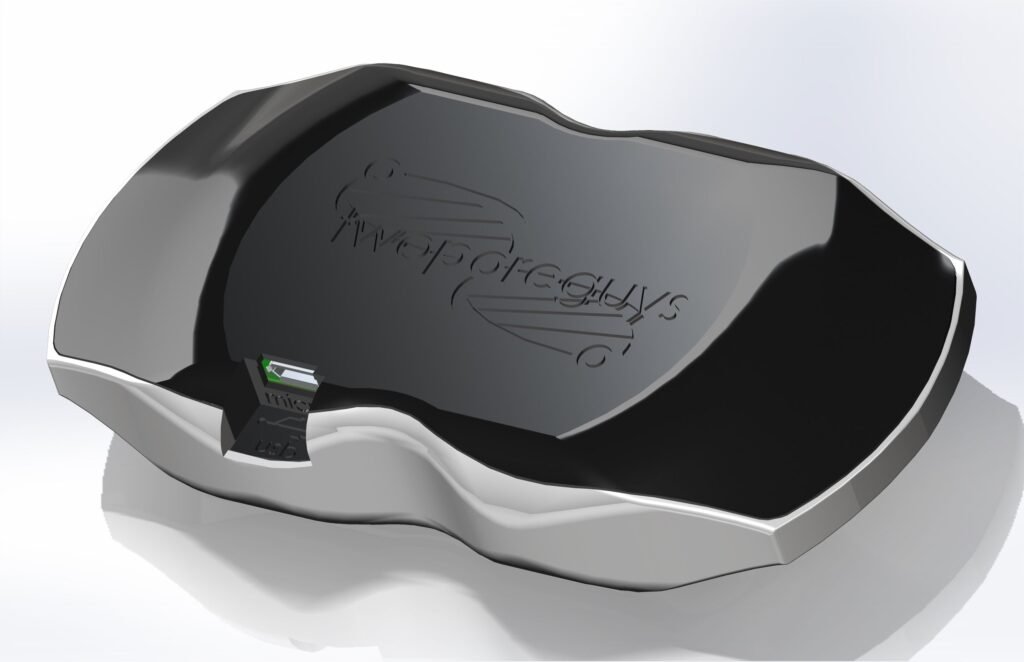

Cleaning up the print with dremel work, several stages of wet sanding, repair techniques to gouges and chips, and a couple of polishing stages result in this case having a finished appearance.

Unlike the 3D rendered illustrative design, a couple of changes were made to quickly get around hardware constraints to produce a working prototype – such as the USB placement, the lack of a screen, and there being one square light spot further in rather than two pairs of wavy light lines near the outer edge of the device.

Due to TwoPoreGuys’ technology taking on an unconventional size and appearance by biotech industry standards, a case was often used by the CEO to help convey the company’s vision to investors that it is achievable.

Some cases were given functioning internals so they could be used for live demos, further selling TwoPoreGuys’ technology and device as being a proven concept rather than mere theory.