CAD, CAM, & CNC Machining

Machined Aluminum

Adapters

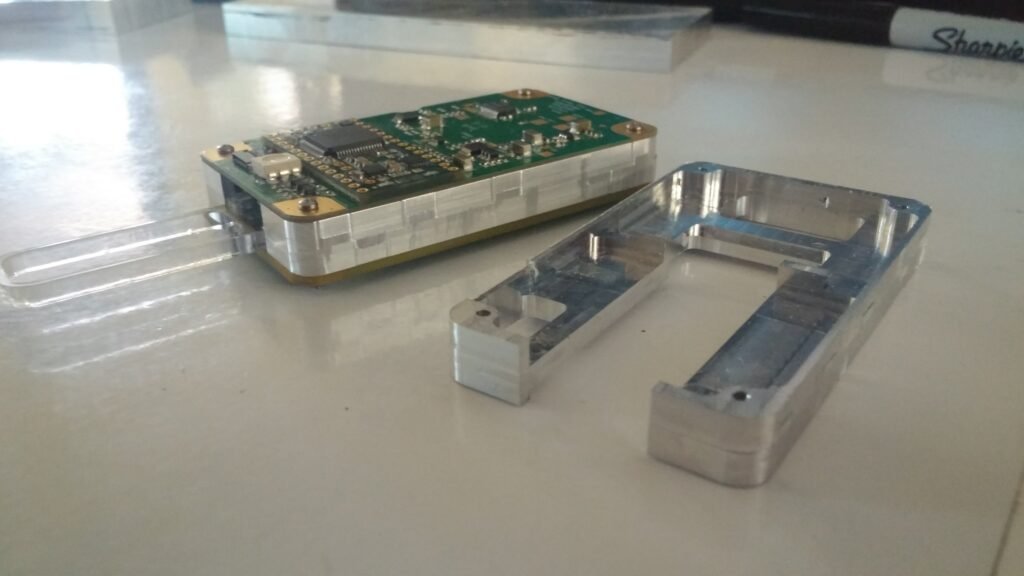

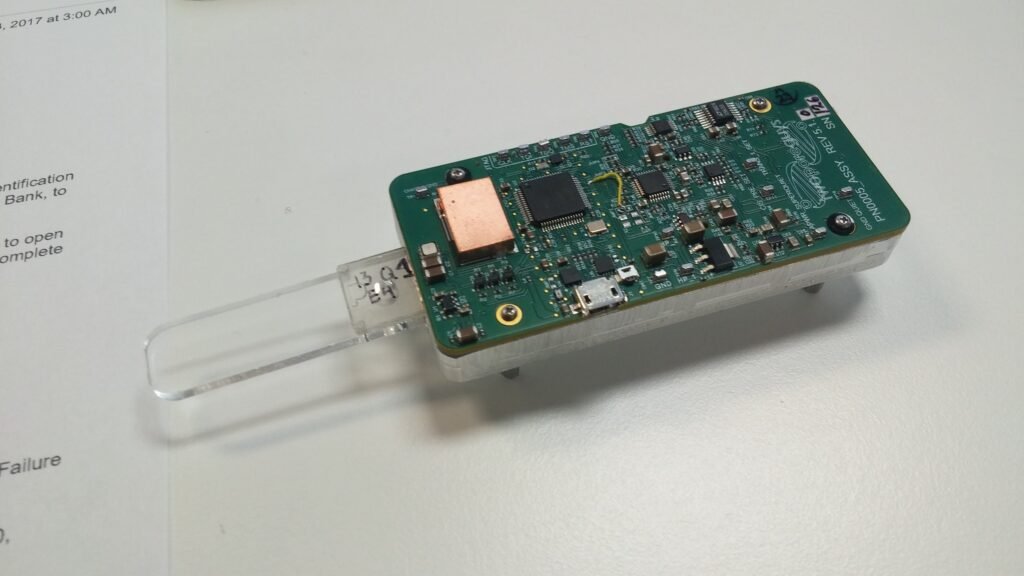

The universal biosensor was an amplifier designed to accept a consumable that interfaced with connectors. A custom adapter was needed to allow this.

Early iterations of this adapter were 3D printed until it was discovered that sensitive bits on the amplifier picked up interference.

Electrical engineering with PCB optimization and board-mounted Faraday cages were used to help isolate interference.

Making the adapters act as Faraday cages for the consumable helped, starting with using EM shielding sprays to coat 3D printed adapters.

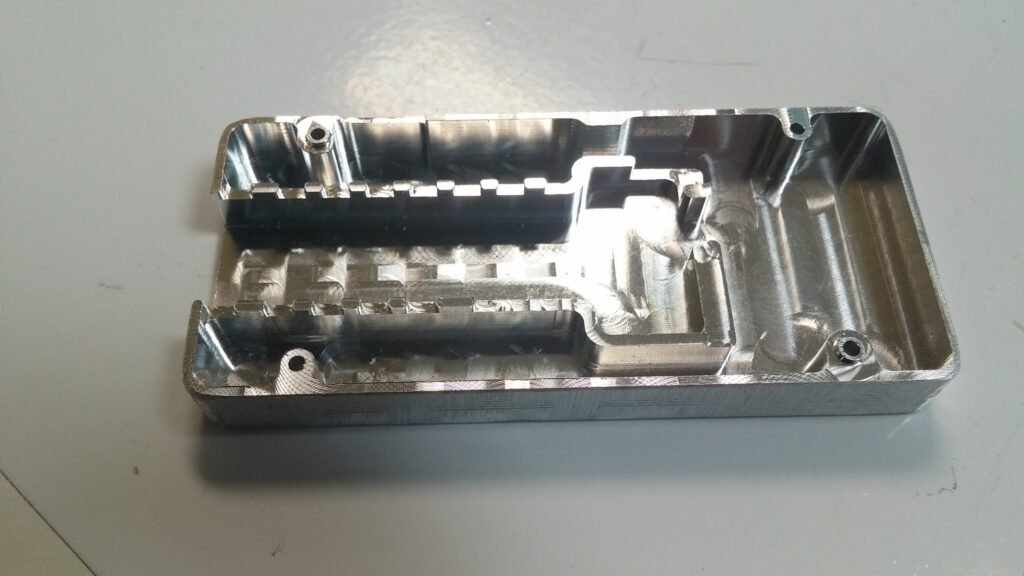

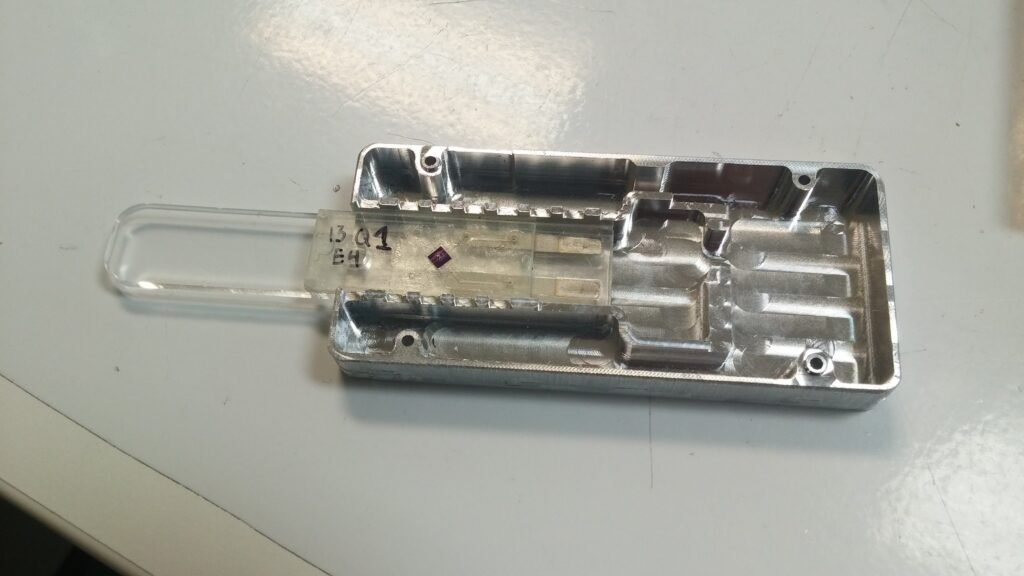

The drawback of the sprays was that when the formula used for manufacturing the spray changed, it began eating 3D-printed adapters. To solve this issue, I designed and machined aluminum adapters.

The machined adapters’ durability, greater tolerance holding, precision, and resistance to buffer despite being a metal was a great benefit over 3D printed adapters.

Groups of lab research assistants would use “naked” versions of the adapter setup, an adapter with an amplifier without a case, to run tests.