3D Models, CAD, CAM, CNC Machining, 3D Printing, Thermal Design

Orca “Nelson” Prototype

The 3D Printed Helix “Orca” Mock-Ups were looked at as an impressive and progressive step towards realizing TwoPoreGuys’ universal biosensor in having taken the concept to reality.

From display pieces to trade-show props, to functional units with working amplifiers that could conduct demos of single-molecule-detection, the Helix Orca mock-ups were progress for TwoPoreGuys despite the mock-ups not entirely matching promoted 3D video illustrations.

Thus the next goal was set – make the Helix Orca resemble that of the videos. At the time, this couldn’t be entirely achieved with the current state of development for TwoPoreGuys’ single-molecule-detection, the lack of integrated hardware components, and the fluidics and chemistry that helped to drive the technology.

Additionally, hardware limitations crunched deadlines for a JP Morgan Conference, and an aim to impress and win over more investors led to two Orca “Nelson” Prototype projects.

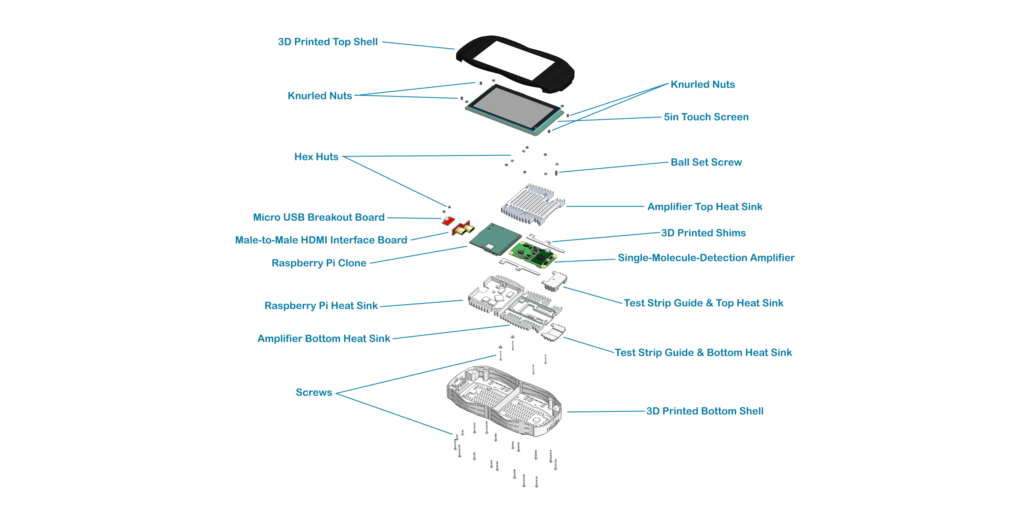

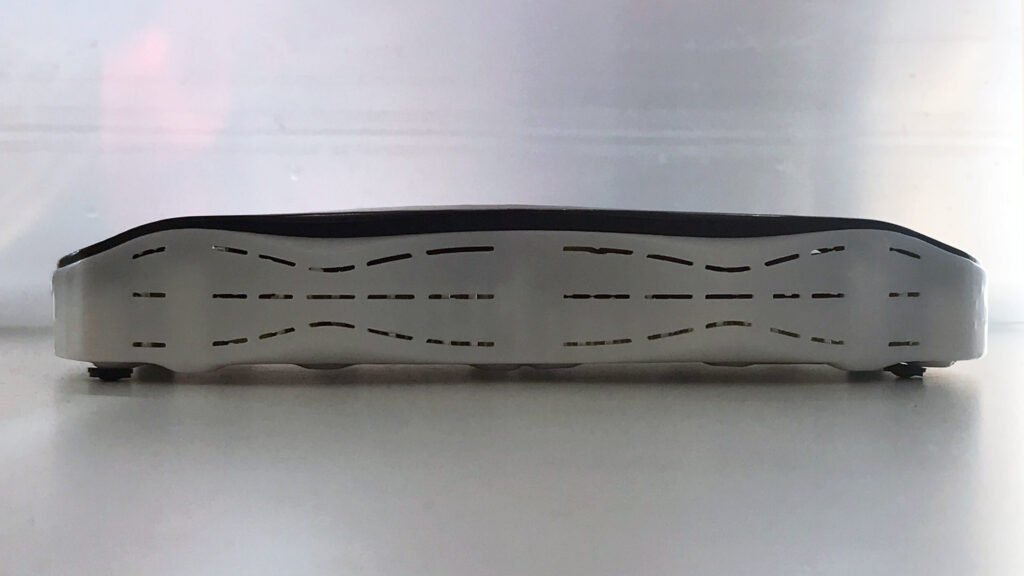

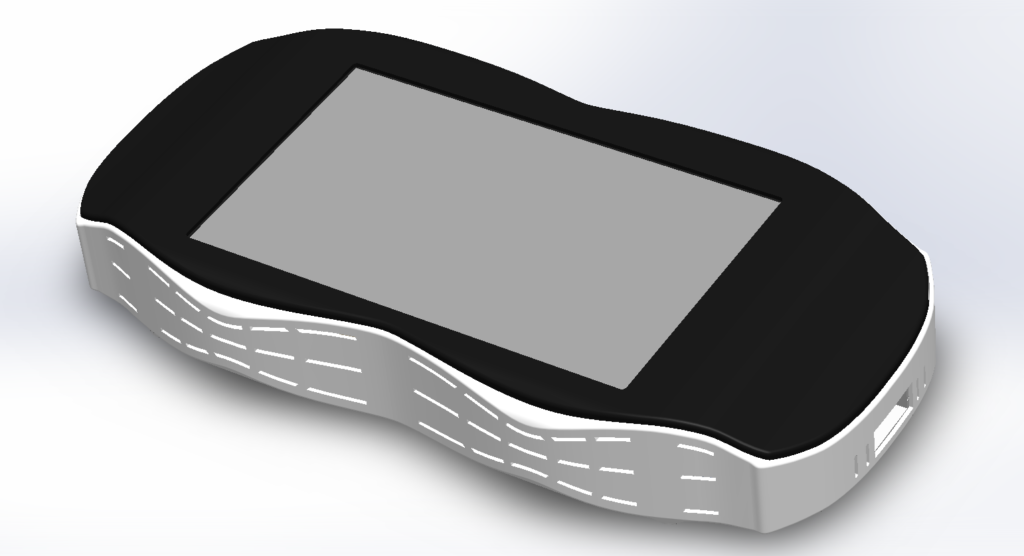

The Orca “Nelson” Prototype was aimed to make a fully functional universal biosensor. The size was found to more than likely be similar to Sony’s PSP considering the desired screen size was around 5 inches.

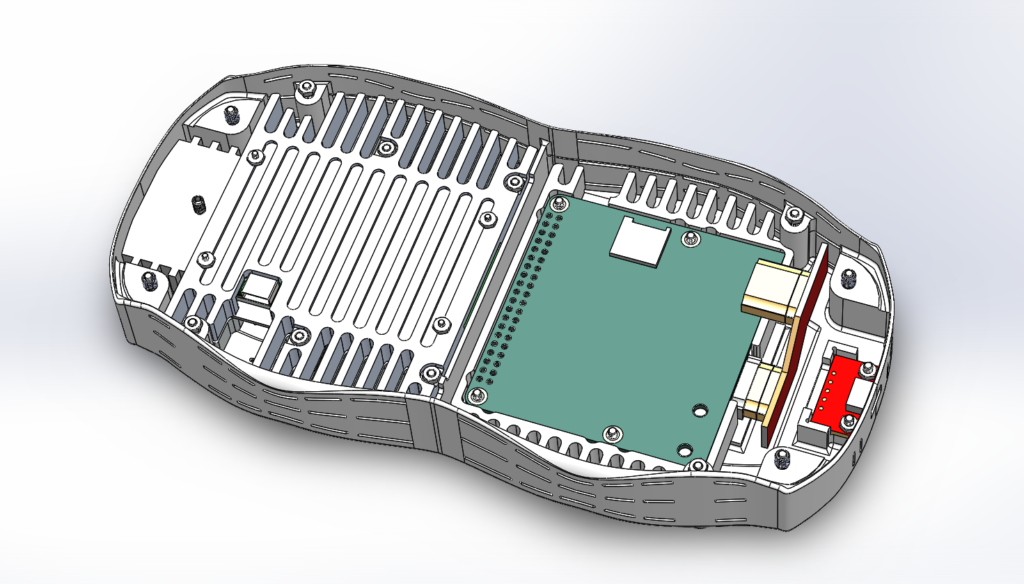

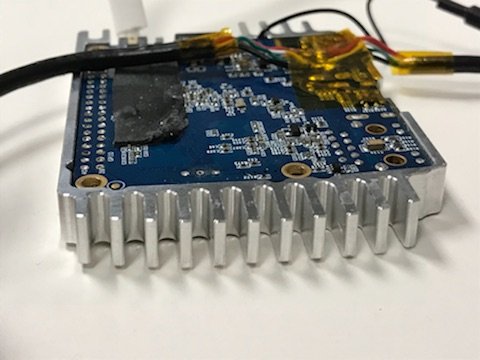

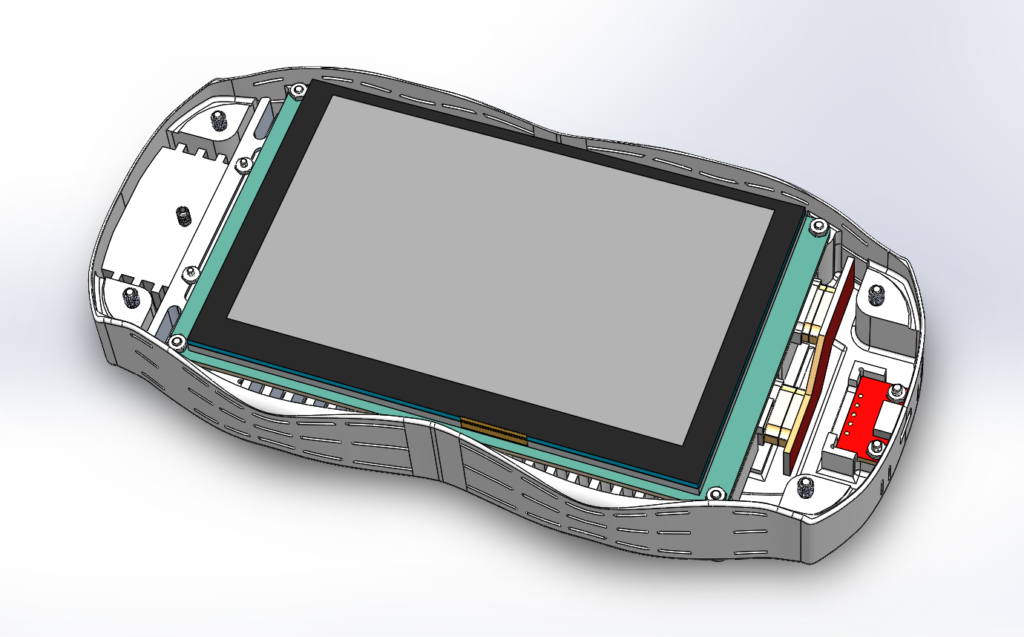

The lack of integrated hardware resulted in the Nelson being about 1 inch thick. The Raspberry Pi Zero PCB and the touchscreen used produced quite a bit of heat inside the enclosure, which was a major issue.

Merely holding the setup in hand was enough to throw off results due to the heat transfer. As a solution to the heat, customary aluminum heat sinks, vented cases, and heat shielding were designed, produced, and incorporated into the Nelson’s design.

The Raspberry Pi Zero PCB’s heat sink used thermal padding and raised portions within to wick heat away from all hot components, while the amplifier had exposed copper on its corners which were used to wick heat away.

Both sets of heat sinks were kept separate – insulated from one another via the plastic of the Nelson’s shell and heat shielding.

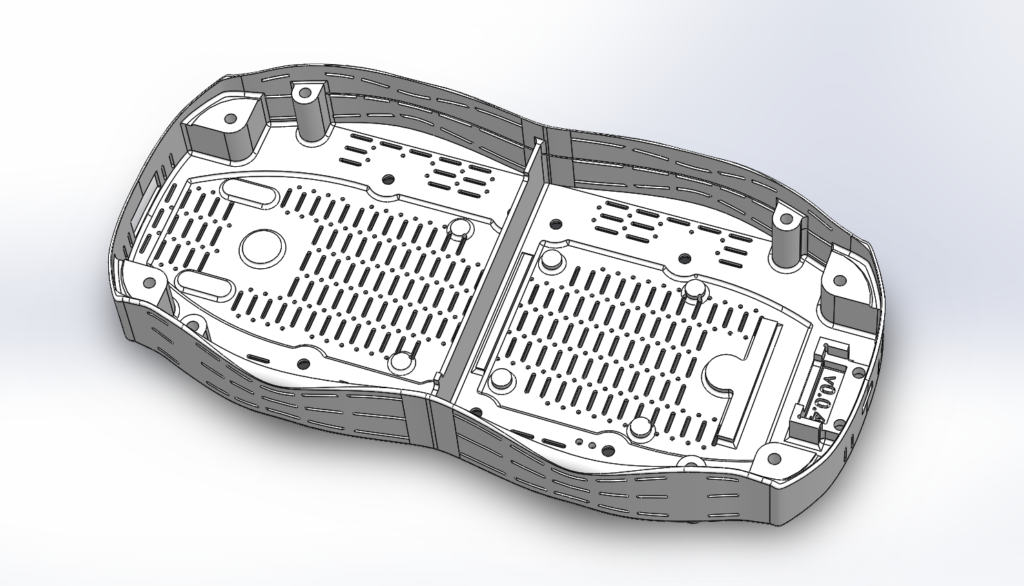

The white, bottom plastic shell of the Nelson was vented to allow air to flow while insulating the heat sinks from physical touch when handling.

To add to keeping the test strip cool, the leading insert for the test strip was also a heat sink.

Due to the unconventional size and styling of Nelson when compared to many wide-ranged diagnostic test devices on the market in the biotech sphere, it was seen as surprisingly small and impressive as a universal diagnostic test solution.